The history of the folding box

These days, it's hard to imagine a world without shipping boxes with bubble wrap for merchandise shipments and outer packaging. Even the post office keeps vast quantities of cardboard boxes and slip lid cardboard as shipping sleeves to keep everything running. We may take the folding box for granted today, but at the end of the 19th century it was way ahead of its time. Its invention originally resulted from a production error and is credited to American inventor and entrepreneur Robert Gair.

In the beginning was the box: The forerunner of today's folding box as protective shipping packaging was the wooden crate until the 19th century. The material used was unplaned boards nailed together with metal pins to form packaging in various sizes. At that time, moving boxes or shipping bags were still unthinkable.

As a packaging material manufacturer and printing experts since 1961, we offer various printed labels, folding cartons and also unprinted custom boxes for shipping for online price calculation on our website.

From the beginning of the 19th century, lighter chipboard boxes came increasingly into use as transport packaging. They were the direct predecessors of the cardboard box as transport packaging. However, laboriously handmade boxes for consumption and everyday use had already existed since the 17th century.

Beginning in 1867, the Scottish immigrant Robert Gair produced paper bags for packaging purposes on specially developed machines in Dumbo (Down Under the Manhattan Bridge Overpass), a residential, industrial and commercial area in the New York borough of Brooklyn. By the end of the American Civil War in 1865, paper had increasingly replaced the cotton or burlap packaging for foodstuffs, such as flour and sugar, that had been typical until then. The scarce cotton was needed for uniforms and the cotton plantations in the southern states either suffered from a labor shortage or supplied (unofficially) to the enemy in the north.

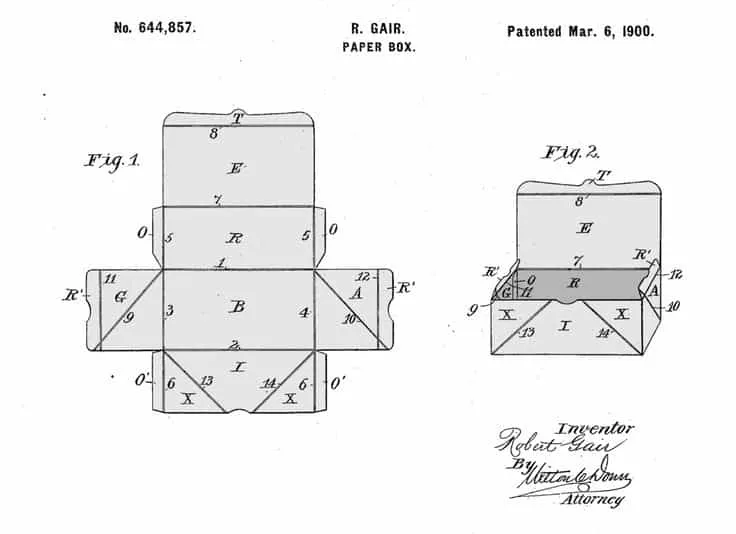

Due to a mistake, a worker at his factory cut up 20,000 paper bags for packaging seeds in 1879. This loss inspired Robert Gair to think about a more effective, prefabricated paper container for packaging food and other goods. In the same year, he developed a process for punching and creasing paper or cardboard in a single operation by machine and designed the first folding box pattern that could be produced by machine. Shortly afterwards, he patented a machine for producing folding cartons.

Folded cartons for transporting products already existed at that time, but they were cut and folded by women in laborious home work and were therefore very expensive. With his inventions, Gair founded the folding carton industry and initiated a revolutionary development of the packaging industry with his life's work. These inventions were accompanied by other important patents: The American Albert Jones patented corrugated paper as a protective material in 1871. The origin of corrugated board was born. Jones first used corrugated paper for packaging purposes, namely for wrapping and shipping bottles and glass vials. His inspiration for corrugated paper appears to have been textile ruffles, which were made using so-called pleating machines. In the early days of custome-made cartons, the large cartons still had to be glued by hand. In 1879, machine cutting and punching was developed in the USA and the first industrial gluing machine was patented in 1895.

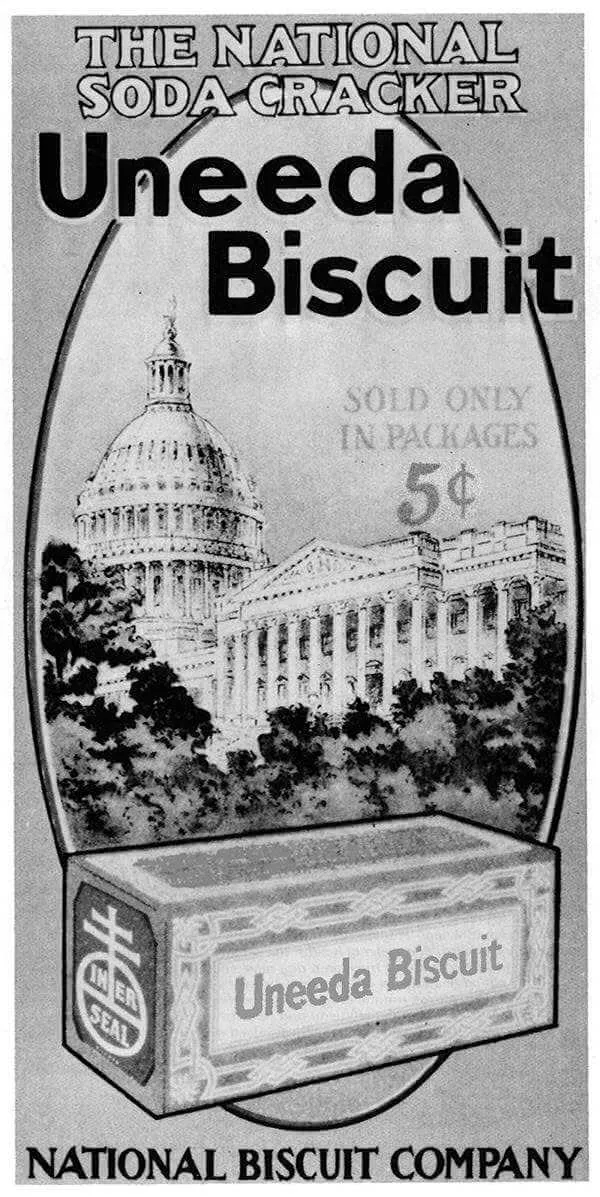

The need for suitable packaging materials for the newly emerging branded goods and "stores'' grew enormously at the turn of the century, the age of the industrial revolution. Robert Gair's folding boxes became an absolute hit. He produced packaging for the Bloomingdales department store, for Colgate to package soaps, detergents, tooth powder and toothpaste, for Pond's beauty creams and some cigarette brands, among others. But his real breakthrough came in 1896 with the packaging of Nabisco`s popular "Uneeda Biscuits'' in folding cartons. Robert Gair produced the first two million boxes for the National Biscuit Company, cereals followed. Consumer convenience packaging was born. Uneeda was one of the first mass-produced branded products not limited to one region. National Biscuit Co. launched the first prepackaged biscuit with the slogan "Lest you forget, we say it yet, Uneeda Biscuit." ("Lest you forget, we say it yet, Uneeda Biscuit ''). This may have been the world's first multi-million dollar advertising campaign.

Interestingly, it is precisely the constant direct repetition of the brand name that is increasingly to be found in today's advertising world - typical example "Seitenbacher muesli". From now on, the packaging of small quantities was no longer done in the "stores" out of large bags or containers, but already in the factory at the manufacturer. However, it was not necessarily the size of the packaging or the speed with which it was packaged by machine that decisively promoted the triumph of folding cartons. For the manufacturers, it was above all the possibility of printing advertising on all six sides of the folding carton! With advertising on the packages, ads in magazines, and promotion on large billboards, the manufacturers took control of the market, not the retailer. Candy, cigarettes and crackers were now available at the POS not in unlabeled tins, but in printed folding cartons, attractive merchandise shelves and creative store displays.

Until the end of his life, Robert Gair not only perfected "his" folding boxes, but also dealt with the lithographic process of printing advertising. His inventions were adopted in England by E.S. & A. Robinson, a long-time business partner, and quickly spread beyond the British Empire, throughout the world. Robert Gair died a rich man in 1927, and his inventions completely revolutionized the world of packaging, consumerism and advertising. With the shipping box made of solid board and with the invention of corrugated board, the history of shipping packaging was decisively shaped. Their good material properties, their protection factor, the low dead weight and, last but not least, their versatility soon made folding cartons the No. 1 material for shipping - and they have remained so to this day.

Product Advisor for Shipping Boxes

Whether it’s a simple folding box or a maxi letter box with adhesive strips – I’m your advisor for shipping boxes made from corrugated cardboard. Our printed packaging and inlays provide protection for products across almost all industries.

"Security and design? Corrugated cardboard offers both!"

I will be happy to help you personally.

Fascination folding boxes

Without exaggerating, it can be said that without industrially produced folding cartons, today's goods traffic, and thus our consumer society, would not exist at all. Folding cartons are available on a massive scale. Folding cartons are simple, inexpensive packaging materials made of cardboard, corrugated cardboard or foil, which are sent to the respective packer folded up to save space and then erected manually or by machine and filled with a product. And folding cartons can be easily combined with other packaging materials. There is nothing complicated about the principle of the "folding box"; what is spectacular, however, is the efficiency with which folding boxes, despite their simple structure, can fulfill several primary packaging functions at the same time.

From the point of view of product packaging, folding cartons are universal all-rounders: they protect the packaged goods, they can be stacked and transported easily, they can be labeled on all sides, and their surface is a perfect advertising medium. It is precisely the combination of these properties that makes folding cartons so fascinating for professionals in the graphic arts and packaging industries.

"Well packaged is half sold": From the consumer's point of view, the contents of the folding carton and the external visual and haptic appearance form an inseparable unit. It is not the goods that are the product, but the goods and the folding carton together that form a product unit. The packaging is the first thing that is perceived during purchase; it provides orientation in the range of goods and, along with other important factors, influences the purchase decision at the POS.

The environmental friendliness of a product is also judged by its packaging, and a folding box made of cardboard or corrugated board is, after all, more environmentally friendly than packaging made of plastic, tinplate or aluminum. A large proportion of the folding cartons produced in Germany are made from waste paper and wood, which is produced when European forests are thinned. Folding cartons can be easily recycled throughout the country.

Last but not least, there is hardly any other print product that is subjected to such an elaborate finishing process as the folding carton. Product designers and media designers are constantly creating new shapes and motifs in order to optimize the emotional impact of folding box packaging on the purchasing decision. Their task is also to combine emotion with factual information content. Every year, competitions such as the German Packaging Award or the ProCarton/ECMA Carton Award bear witness to the endless creativity and ingenuity of the packaging industry and leave print professionals amazed at what is possible.

The naked truth is: brick-and-mortar retail is crumbling away, and only those who have managed to build up an online rail (multi-channel) parallel to their brick-and-mortar business can look to the future with optimism. All predictions indicate that online retail will continue to grow very strongly in the near future. Online retailers turned over almost 25 billion euros in Germany in 2015, a good 13 percent more than in the previous year. E-commerce thus remains one of the fastest-growing sectors of the economy. But what significance does this development have for folding cartons?

The folding carton is the number 1 packaging material for online trade

Consumers who shop online pay close attention to product quality, freshness, deliverability, selection, and reliable service - all of which labels and folding cartons must provide. The folding carton is not only the most important product protection, but also the central brand ambassador, both when pictured in the online store, on the shelf, and with the consumer at home. Folding cartons made of cardboard or corrugated board are the number one packaging material for online retail because they can be easily imaged in the web store, because they best meet logistical requirements, and because the cardboard makes them the most sustainable packaging material.These theses are confirmed by a study conducted by the renowned EHI Retail Institute on behalf of Pro Carton, the marketing association of the European cartonboard and folding carton industry. Marketing managers of leading retailers in Germany were surveyed. Folding cartons are preferred over all other packaging by 80 percent of those surveyed. The question asked was which product packaging meets the shipping requirements particularly well. According to the survey, respondents consider pouches (56 percent) and blister packs (40 percent) to be far less suitable. At five percent, glass was at the very end of the scale.

Why do respondents prefer to send folding boxes?

Mainly for four reasons: They can be photographed well and thus optimally displayed in the online store. Folding boxes protect their contents and do not damage other products in the shipment. They can be used as an all-in-one solution, meaning they can be used as product and shipping packaging in one. And they go down well as gift packaging.

These articles may also interest you:

GC1 - coated chromo board

The GC1 board is a so-called chromo board. The chromo board is a multi-ply board made of pulp, wood pulp or wood-free waste paper with a coated, flat surface.

Silver cardboard for folding boxes

In today's age of self-service, packaging must sell the product. Whether a customer is attracted to a package depends on its color, shape, function and size.

Chromoduplex board GD2: recycled folding boxboard

In the calculator you have the possibility to choose between a variety of materials. These materials belong to different groups and have different properties.