Printed labels

Printed labels

Are you in need of an opaque, numbered, or metallic label? Or perhaps a label suitable for thermal printing and frozen goods? Printed labels from Labelprint24.com provide professional and customised solutions for all your product marking needs.

- Fast production and free delivery

- Cutting-edge manufacturing for premium quality

- Wide range of label accessories

Select your product and calculate it directly online now!

- Production TimeFrom 48hr

- MaterialFilm / Paper

- Size100% customizable

- Finish OptionsFilm / Varnish

Select kind of product

What are printed labels?

Printed labels are labels on a roll, which are often also referred to as adhesive labels on a roll, stickers, adhesive labels, roll labels, bottle labels or self-adhesive labels. Adhesive labels are used universally, especially on bottles, cans, jars, printed packaging and other containers. The industrial sectors can be very different. They range from the chemical, food and beverage industries to the cosmetics industry and many more. Depending on their intended use, printed labels must be short or long-lasting, food-safe, water- and scratch-resistant, UV-resistant and chemical-resistant.

Patterns made to measure. Simply order online.

The sample box from Labelprint24 offers you an exclusive selection of products, printed and finished in our company design. We will refund the full purchase price of the sample box in the form of a voucher if you decide to place an order with Labelprint24. The voucher is of course valid for all products in our webshop.

In this box you will find samples of single and multi-layer roll labels, folding cartons, laminate tubes and package inserts.

Printed labels fit into manual or automatic label dispensers, which have a rotating dispensing system and therefore enable a high labelling speed. The printed labels on rolls guarantee the required speed, secure adhesion and economic efficiency: these three factors are decisive for industrial labelling with adhesive labels and stickers. Labels on rolls are used as roll labels or sheet labels in all industrial sectors, at public authorities, universities, in the office or at home.

At Labelprint24, you can find labels on rolls in all common formats and materials. From paper to film labels, as well as permanently adhesive and removable labels.

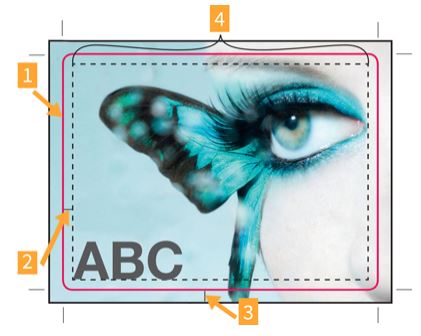

Print data for your labels

Roller core and carrier material

The printed roll labels consist of two main parts: the roll on which they are wound and the material on which the labels are stuck

Winding on roller core

As the name suggests, printed stickers, which are produced as roll labels, are wound onto a roll after printing. This requires a roll core made of thick cardboard, the diameter of which is matched to the customer's existing label dispenser. Theoretically, any roll core diameter is possible, but in practice the standard diameters of 26, 40, 50 and 76 mm have become established. When rewinding onto the corresponding roll core, it is essential to observe the winding direction so that the labels are correctly dispensed onto the product to be labelled at the customer's premises. The printed labels on the roll are always wound so that they are either on the inside or outside of the label roll.

Carrier material

The carrier material, on which the label remains until it is removed and glued after printing, consists of thin glassine or kraft paper or a special film material for high-performance labelling machines. As the backing material is often provided with a silicone release liner on the adhesive side of the roll label, the printed label can be easily removed from the backing material if required. The liner tape is no longer required after labelling and is then disposed of and recycled.

Application of printed labels

The types of printed stickers are as varied as their areas of application. The labels range from inventory labels in the office to operating labels on machines and systems. Depending on the area of application, the requirements for the label are diverse. These include criteria such as moisture, temperature, chemicals, uneven or oily surfaces, sunlight and high abrasion.

Labels are used in applications where

- Work safety,

- Hazardous substance labelling,

- Information management,

- Tamper protection,

- Safety labelling,

- product labelling or

- in the office and administration.

Typical areas of application for printed roll labels

- Labelling food with food labels

- Numbered barcode labels in the transport and logistics industry

- Transport stickers for labelling containers with chemicals

- Weather-resistant film labels for the chemical and automotive industries

- Labelling of technical components

- High-gloss labels and transparent stickers for cosmetics

This list of applications for printed labels could go on and on. The interesting thing is that almost every industry has very individual requirements for the roll labels that need to be taken into account when printing labels.

Examples of industry-specific labelling requirements

- Labelling with food labels usually takes place under the most difficult conditions, for example in wet or greasy environments or at freezing temperatures. In the sensitive food industry, many legal requirements such as REACH conformity, food labelling or the Food Information Regulation Act must be taken into account. It must also be ensured that there is minimal or no migration of microscopic adhesive and labelling material components of the food labels into the food.

- For most products used in the chemical industry, approval in accordance with ‘British Standard 5609 Section 2’ is mandatory. This means that the printed labels can be stored in salty seawater for three months without detaching from the labelled container on the container ship during the sea voyage.

There are therefore various industry-specific factors to consider, which usually have a significant impact on the label materials to be printed. The choice of label printing production process is also influenced by the order volume and intended use, as well as the requirements for further processing.

Lesen Sie mehr Informationen zu Industrieetiketten und Spezialetiketten.

Read more information about industrial labels and special labels.

There are therefore various industry-specific factors to consider, which usually have a significant impact on the label materials to be printed. The choice of label printing production process is also influenced by the order volume and intended use, as well as the requirements for further processing.

Materials for printed labels

Printed self-adhesive labels, regardless of whether they are roll or sheet labels, basically consist of a backing material, pressure-sensitive adhesive, a face material and printing ink. Printing experts refer to this label structure as an adhesive bond. Optionally, a transparent varnish and/or a metallic film can be added. After printing, roll labels are rolled onto a cardboard roll core in the quantity required by the customer. The upper material of the labels carries the printed image and can consist of label paper or label film.

Label paper

Printed labels made from label paper are the cheapest to buy. However, they are only suitable for short-term outdoor use, for indoor use or in places where they are sufficiently protected from moisture, wind and weather. There are many types of label paper with different grammages, surfaces and structures. An optional blue back coating gives the label paper increased opacity. A special label paper for the pharmaceutical sector has a low paper thickness and is therefore more supple. It adapts ideally to highly curved surfaces, such as ampoules.

Our material properties of paper labels at a glance:

- Matt paper, permanent adhesive

- Matt paper, removable adhesive

- Matt paper, permanent adhesive, suitable for deep-freezing

- Matt paper, permanent adhesive, opaque for opaque labels

- Glossy paper, permanent adhesive

Calculate now as labels on a roll for your application:

Metallised paper labels

Printed labels made from metallised paper have a layer of fine, laminated aluminium foil, which is applied to the paper surface during paper production. Printed labels with this metallic paper composite have a metallic sheen, such as silver or gold, depending on your requirements. This paper is ideal if the labels are to have a high-quality, metal-like effect, as is usual with cosmetic labels.

Our material properties of metallised paper labels at a glance:

- Metallised paper, SILVER glossy, permanent adhesive

- Metallised paper, GOLD glossy, permanent adhesive

Calculate now as printed labels for your application:

Luminescent-coloured paper labels

Printed labels made of fluorescent paper, also known as neon or fluorescent colour paper, have a high signalling effect and are mostly used as price labels. The typical yellow, red, orange or green colour is created by colour pigments that are coated onto the base label paper during paper production.

Our material properties of fluorescent papers at a glance:

- Luminescent-coloured paper, GREEN, permanent adhesive

- Luminescent-coloured paper, RED, permanent adhesive

- Luminescent-coloured paper, ORANGE, permanent adhesive

- Luminescent-coloured paper, YELLOW, permanent adhesive

Calculate now as printed labels for your application:

Printed labels made from thermal paper

The best-known application of printed labels made from thermal paper are roll labels for direct printing in the self-service area of supermarkets. The scales available there with integrated label printers print out a label as a receipt with an EAN or barcode, weight and price, i.e. with data that is only compiled individually shortly before printing. The typical black colouring of the printed image on thermal paper labels is made possible by a special reaction ink, the thermal coating, which is applied to the base label paper by the paper manufacturer. When producing roll labels from thermal paper for direct printing, it is important to have a protective layer on the surface so that the reaction colour is not activated during printing in the label printing plant.

Our material properties of printed thermal paper labels at a glance:

- Thermal Eco paper white, matt, permanent adhesive - for standard applications

- Thermal Top paper white, matt, permanent adhesive, with protective coating for long-term use

- Thermal top paper white, matt, permanent adhesive, with protective coating for long-term use, suitable for deep-freezing

Calculate now as printed labels for your application:

Printed labels made from label film

Printed labels are increasingly being made from label films. Label films such as PE, PP or PVC have several advantages over paper labels. They can also be used outdoors without any problems. Printed film labels are extremely robust and have excellent resistance to environmental influences such as moisture, acids, chemicals, UV radiation or greasy substances. It is possible to produce transparent labels with plastic film labels. Transparent labels are used for labelling cosmetics and drugstore products, among other things. With transparent labels, the labelling appears to be printed directly onto the product. The ‘invisible’ printed label achieves a very high-quality appearance thanks to the transparency effect.

Our material properties of the printed label films at a glance:

- PE film white, glossy, permanent adhesive

- PE film white, glossy, extra-permanent adhesive

- PE film white, matt, permanent adhesive

- PP film white, glossy, permanent adhesive

- PP film white, glossy, removable adhesive

- PP film white, glossy, permanent adhesive, suitable for deep-freezing

- PP film white, matt, permanent adhesive

- PP film white, matt, removable adhesive

- PVC film white, glossy, permanent adhesive

Calculate now as printed labels for your application:

Security labels

Security labels consist of paper, film, ink and permanent adhesive. With a hot-melt adhesive, the sealing labels adhere to critical surfaces such as steel, glass, damp plastic or building materials. Security labels are used to detect tampering attempts on products, to seal high-quality products and to mark property. Security labels are an inexpensive, efficient and indispensable component of product security.

- VOID PET film, white, transparent

- VOID PET film, with hologram

- Security label made of paper, opaque, peelable and self-destructing

Calculate now as printed labels for your application:

Read more information about printing labels on film and paper.

Printing process for printed labels

Printed labels on rolls are printed either on digital printing systems or using the conventional flexographic printing process. The print quality is excellent with both processes. We offer both technologies as alternatives in our online calculator.

What factors determine the optimum printing process for labels?

- Label order volume

- Label material

- Requirements for migration

- Additional functions of the labels

- Requirements for personalisation

With our digital printing systems, we are able to personalise roll labels with individual data. This data can be consecutive numbers, codes or changing print motifs, for example. Printed labels can be produced more cost-effectively digitally for small and medium runs. Flexo printing is more cost-effective for large print runs. The materials available for flexo and offset printing are also somewhat larger. For labels with indirect food contact, you will find the right label of your choice among our food labels.

Adhesive roll labels

Type your text

You can already select which materials, adhesives, colours and finishes are suitable for you in the calculation. Flexographic printing is the best printing process for high-quality adhesive roll labels with medium and large print runs. This is where it really comes into its own:

- Enormous brilliance and authenticity of the colours!

- Particularly favourable prices for large print runs!

Type your text

We print conventional adhesive labels on rolls in all formats, rectangular, round, oval, large and small. We produce your printed roll labels as self-adhesive, removable or with a suitable deep-freeze adhesive. Of course, we can also finish your roll labels with hot or cold foil as required. Depending on the configuration, the adhesive roll labels with conventional printing from Labelprint24 can be used both indoors and outdoors. Our UV varnish ensures perfect weather and UV resistance. We supply your custom-printed roll labels in the desired quantity, pre-wound on roll cores made of sturdy cardboard in the usual core diameters of 26 to 76 mm.

Adhesive roll labels in flexographic printing

Flexographic printing is a so-called letterpress process in which the ink is transferred to the substrate, which runs between the printing plate and the impression cylinder, via a raised, flexible printing plate (cliché). Compared to other printing processes, flexographic printing has the invaluable advantage that a wide variety of materials can be printed on, from simple paper to laminates, from plastic film to cardboard. No other industrial printing process has a similarly wide range. It also sets standards in terms of environmental friendliness.

Flexographic printing of roll labels is particularly well known for the brilliance and variety of colours produced using this process. With the basic colours cyan, magenta, yellow and black (CMYK), an unlimited number of colour mixtures and screen areas are possible.

Labels flexo printing vs digital printing

We also print your roll labels using conventional printing in all special colours from the so-called HKS, metallic colours or Pantone palette. These special colours are already mixed and have a bright, intense quality with rich solid areas. Production of roll labels - wide choice and flexibility with conventional printing of roll labels, there are almost no restrictions regarding the choice of materials to be printed on. Any paper weight, the so-called grammage, any surface, any quality, even PP, PE and PVC film can be printed effectively. Due to the large selection of material variants and paper thicknesses, flexographic printing of roll labels is more variable than digital printing.

Unlike flexographic printing, digital printing does not require an elastic printing form, which means that each roll label can be printed (personalised) differently.

As a general rule, the smaller the print run, the more economical digital printing of adhesive labels on rolls is compared to conventional printing. From print runs of 50,000 - 100,000 pieces, flexographic printing is usually more cost-effective. Thanks to the use of innovative technology and state-of-the-art digital printing systems, such as the UV inkjet machines installed at Labelprint24, you can have even medium-sized runs of roll labels produced by us just as cheaply and in super quality.

The choice of printing process (digital or conventional printing) for the production of your customised adhesive labels on rolls is always a question of the print run, the quality, the planned production date and, last but not least, the price. We will be happy to help you decide on adhesive labels on rolls using flexographic printing or digital printing. Simply calculate your adhesive labels on rolls online as required.

Direct thermal printing & thermal transfer printing in comparison

Thermal, i.e. temperature-dependent, printing processes always require a hot print head, the thermal comb with the dots (special semiconductor resistors) and a specially coated, temperature-sensitive material. There are essentially two widely used printing processes for thermal printers.

In direct thermal printing, the print head heats a thermosensitive material. The colour of the thermal paper changes at the heated points and black numbers, letters and/or screens become visible, whereby the print quality is not so important. This simple technology is cost-effective, but the printed information fades over time due to exposure to light and heat. The advantage of direct thermal printing is that it does not require any additional consumables, such as colour ribbons.

Thermal transfer printing is somewhat more complex and produces a better, coloured print image. This technology requires a colour ribbon. The heat causes the print head to transfer the colour from the thermal transfer ribbon to the material to be printed. Any normal labelling material can be printed on with a thermal transfer printer. The print quality and resolution are significantly better and the materials used are more durable. As labelling specialists, we know what makes our customers' work easier and offer perfectly matched labelling accessories. Hand label dispensers and table label dispensers in various designs are a must. We are also happy to offer you quantity discounts on our label dispensers of all kinds within our graduated prices.

Products and further processing

Writable labels, so-called blank labels, are suitable for labels that you want to print yourself. Such blank labels are used in pharmacies, for example, to label goods with content information or expiry dates or for foodstuffs such as jams. Suitable thermal tape and printers are required for this. If you want to have labels printed, you can do this with the help of our calculator.

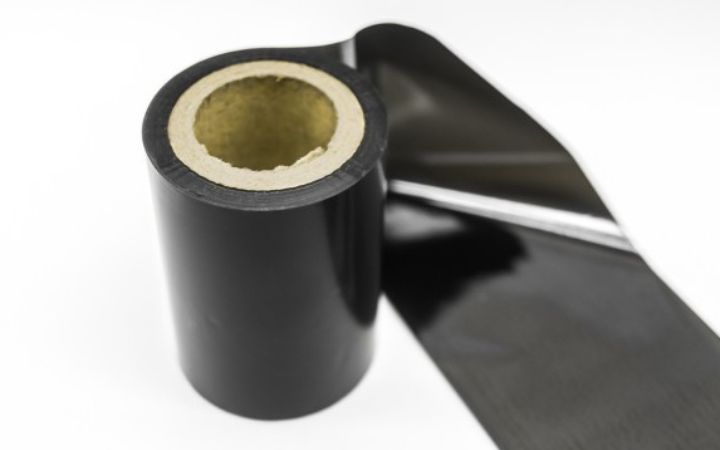

Thermal ribbons

Whether desktop or industrial printer: our selection of thermal transfer ribbons provides the right quality for every common printer model and virtually every substrate. Thermal transfer ribbons from labelprint24 are suitable for rough and smooth paper as well as various plastic surfaces, are gentle on the print head and offer a wide range of design options thanks to the large selection of colours.

Thermal transfer ribbons are consumables for thermal transfer printers. Their special printing units use thermal transfer to transfer the dyes transported on the thermal transfer ribbon to paper, film or other substrates. By heating the carrier material, the liquid colour is then applied to the substrate with the help of a roller.

There are many different areas of application for thermal transfer ribbons and thermal printers: Whether in retail, public authorities or the healthcare sector. Tickets, parking tickets or textile labels are often produced using thermal transfer printing. Wax thermal transfer ribbon is often used for printing logistics labels (e.g. shipping labels, pallet stickers).

Thermal transfer ribbons consist of a 3.5 to 6 µ (thousandths of a millimetre) thick polyester film, which is coated on one side with a 2 to 4 µ thick layer of ink. Different proportions of waxes and synthetic resins as well as colour pigments, usually carbon particles (soot), give the thermal transfer ribbon its colour.

Thermal printer

Wherever variable data needs to be printed quickly on a label on-demand, this is the ideal area of application for a thermal printer. The completely uncomplicated printing options, simple operation and relatively simple technology make the thermal transfer printers from labelprint24 an indispensable aid in warehousing, sales and logistics.

Our range extends from compact desktop printers for the office to barcode printers and high-performance industrial printers for industrial labelling.

- All products certified according to ISO 9001

- High resolution, robust and safe operation

Label dispenser from Labelprint24: cost-effective and convenient

Our sturdy table label dispensers made of metal or cardboard and manual labellers for roll labels in various sizes not only make daily labelling easier for you, but also protect your valuable label rolls and keep your workplace tidy. This protects your labels perfectly from dirt and moisture. Applying labels individually to a surface, packaging or product is very time-consuming and impractical without manual dispensers.

The advantages of our manual label dispensers at a glance:

- Low space requirement and effortless transport

- Up to 5 different label rolls simultaneously in one device

- Easy handling

- Flexible due to quick roll change

- Quick removal of the label from the liner

- Robust workmanship and durability

With our practical desktop label dispensers, the label is detached and made ready for removal by manually pulling the backing tape forwards. Whether at the production or home workplace, on the shop counter or the sales stand, the manual label dispensers stick your labels firmly and securely wherever you want them. At labelprint24, label dispensers are available in various widths and designs and impress with their absolutely favourable price, first-class workmanship and long service life.

Manual dispenser for printed labels on rolls

In table label dispensers, the individual label rolls are simply inserted and removed roll by roll label by hand. Desk label dispensers fit on any desk or work table and are at home in the office environment. The dispensing speed is not important here, it is more about tidiness and clean storage of the labels.

With the manual labeller, the printed roll labels are fed by pressing a lever on the handle. The individual label is transported via a rubber roller and applied to the object to be labelled. This process works quite quickly, but is still far too imprecise and slow for large label quantities.

Dispensing systems for printed labels on rolls

For the industrial dispensing of printed labels onto large quantities of products, automatic labelling machines with various speed classes are used, which are usually integrated into the manufacturer's packaging lines. A conveyor belt guides the products past the labelling machine and light barriers detect the optimum labelling position. The printed labels are controlled by a microprocessor and attached precisely on, under or on the sides of the product packaging. There are high-speed labellers that can apply up to 5,000 labels per minute.