Film labels

Are you looking for Labels that are resistant to environmental influences? Robust Plastic Labels for outdoor use that are also visually convincing? Film Labels from Labelprint24.com mark your products individually and professionally.

- Labels with permanent or removable adhesive

- Large selection of PP, PE, PVC and PET Labels

- Dirt and water repellent and smudge resistant

Select your Product and calculate it directly online!

- Production TimeFrom 48hr

- Size100% customizable

- Finish OptionsFilm / Varnish

Select kind of product

Film labels from Labelprint24

What are film labels?

At Labelprint24 you will find suitable labels for every application. Our film labels in particular are characterised by their durability and can therefore be used outdoors without hesitation.

Our film labels have a thin plastic layer as the upper material. The layer can be made of different plastic materials. Plastic is a popular material for labels, but there are also paper labels. We also offer paper labels in our range. The film labels from Labelprint24 are characterised above all by their high resistance. Therefore, our labels are suitable for professional and reliable labelling, as they are weatherproof and more durable than paper labels.

Most labels today are made of plastic and are used in different areas. For example, film labels can be made of the following plastics:

- Polyester

- Polyethylene

- Polypropylen

- Polyvinylchlorid

This results in different properties depending on the film material. The high quality and glossy structure of the film make our labels ideal for cosmetic products. Attractive design and practical application are combined here. Our team at Labelprint24 will be happy to advise you in all matters.

Which plastics for labels are available at Labelprint24?

At Labelprint24 we offer different plastic films for your labels. As a label manufacturer, we produce your film labels from polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC). In the following section we will introduce you to the individual plastics in more detail.

Polyethylene

Polyethylene (PE) is a related material to polypropylene. PE is the most widely used plastic worldwide and is mainly used for films and packaging. The plastic is semi-crystalline and non-polar thermoplastic. Furthermore, PE does not contain any plasticisers, heavy metals or silicones and can therefore be easily recycled. Many everyday items that can be bought in supermarkets are made of PE plastic, such as plastic bags, buckets, laundry baskets, carrying cases for drinks and labels.

PE is a material that is resistant to acids and alkalis. However, an additional coating should be chosen for outdoor use, as the film has a high risk of becoming brittle when exposed to sunlight.

The film is temperature resistant at temperatures from -85 °C to 90 °C. The resistance also depends on the crystallinity of the PE film used. The more crystalline the film, the more resistant it is to temperatures.

PE is harmless to human health because it does not contain any plasticisers, for example, and the plastic is also wonderfully recyclable. The main area of application for PE is packaging materials, including PE labels, which are inexpensive to purchase.

Material: PE film + adhesive

Polypropylene

Polypropylene (PP) is a thermoplastic. It is produced by polymerising propene. PP can be flexibly adapted according to the application requirements, e.g. by adding reinforcing and filling materials, additives or also by the processing methods.

In contrast to polyethylene, the plastic is harder, stronger and more resilient, although both materials are chemically very similar. PP is the second most important mass plastic, accounting for around 20 per cent of the total production volume, and has shown the strongest growth worldwide (since 2016).

The plastic is also more resistant to grease, solvents, alkalis or acids. PP also absorbs only a small amount of moisture and is temperature resistant at temperatures from -10 °C to 110 °C.

The plastic is optimally suited for the labels at Labelprint24 and can be used in many areas of application where resistance is important. It is possible to die-cut, fold, print, glue and score PP film labels as desired. It is also important to mention that PP can also be excellently recycled.

Material: PE film + adhesive

PP film white, glossy, permanent adhesive

Polyvinyl chloride

Polyvinyl chloride (PVC) is the third most commonly produced plastic. After 1945, it was even the most produced plastic worldwide for a certain time. PVC has an enormous lifespan and we encounter it constantly in everyday life. It is an amorphous thermoplastic. Without plasticisers and stabilisers, the plastic is hard and brittle. Only by adding these substances does the plastic become supple and malleable.

The plastic is translucent or transparent, but can also be produced opaque and cloudy. PVC is flame retardant, absorbs water well and can also be coloured. A distinction is also made between hard PVC and soft PVC.

Rigid PVC is commonly used for window profiles, sewage pipes and roller shutters. Rigid PVC is therefore often used in mechanical and apparatus engineering as well as in electrical engineering. Soft PVC is equally suitable for artificial leather, furniture, bags and shoes. It is possible to process PVC into fibres. Thus, the material can also be used for home textiles, technical textiles and also for wigs.

PVC labels are also popular in the chemical industry because they are highly resistant to acids, oil and seawater. In addition, the labels adhere perfectly to any surface and are particularly tear-resistant. The labels are resistant to UV radiation and are electrically non-conductive.

Due to their weather resistance, the labels can be used especially outdoors.

Material: PVC film + adhesive

PET security labels

Polyethylene terephthalate (PET) is also a type of plastic and is particularly well known as a material for disposable and reusable bottles. PET comes from the polyester family. Other articles such as packaging, to-go salads or even thin films are also made of PET. PET is resistant to alcohols, fats and oils as well as diluted acids. It is also used for microwave trays, cups, snack and ice cream packaging. PET accounts for 6 per cent of the total amount of plastic produced. It is therefore not surprising that many people have to deal with the plastic on a daily basis.

PET is less harmful to the environment than other plastics and can be fully recycled. It is a transparent plastic and the strongest and most stable plastic material. PET has a few disadvantages like any other material. Drinks made from PET bottles are not entirely harmless. Liquids that remain in the bottles for a long time absorb the substances acetaldehyde and antimony trioxide, which are released by the PET over time.

PET bottles therefore emit more microplastics than other beverage bottles. With the right handling, PET can still be used safely. You are welcome to ask for advice about our labels with PET film from Labelprint24.

VOID PET film, white, transparent

Guide to the selection of suitable label film

Some factors for selecting the appropriate film and adhesive:

- Storage (weather, temperature range, UV stability, humidity, heat, cold, dirt, dust, contact with chemicals)

- Transport(seawater resistance, scratch resistance, ageing resistance)

- Container (surface tension, deformability)

- Further processing (thermal resistance, printing technology)

- Migration regulations(food labels)

The material of the product packaging and its properties are just as important as the label material itself. Especially for packaging made of low-energy plastics (e.g. PE film / PP film) or rough surfaces of other surfaces, extra strong adhesives with a high initial adhesion are preferable. Furthermore, the deformability of the immediate product packaging is decisive for the choice of film material.

Rough guide to choosing film for your labels:

- PE film - for deformable containers that are not subjected to higher thermal stresses

- Cost-effective, toxicologically safe, also suitable for fatty foods etc.

- PP film - For rigid containers that are not deformable and also have to withstand higher temperatures

- More tear-resistant than PE and PVC material

- PVC film - For outdoor storage and for goods with long transport routes overseas or for longer standing times/delivery routes domestically.

- UV stable, ageing resistant, resists seawater

- Cuddly even on uneven surfaces

- Not suitable for food without additional barrier layer due to migration of plasticisers

For which industries are the film labels suitable?

There is no industry in which labels are not needed. Labels, especially film labels, are used every day in the five largest industries in Germany. Millions of labels are therefore needed in the automotive industry, in the chemical and pharmaceutical industry, in electrical engineering, in the food industry and in mechanical engineering. We would like to introduce you to some of the industries and their label use in more detail:

Automotive industry

In the automotive industry, mainly standardised film labels are used, which are particularly hard-wearing and durable. The labels are specifically used for the following products:

- Product recognition and control

- Type plates

- Batch identification

- Anti-theft protection

- Logistics labelling

- Shelf labelling

- Evidence

The information or writings on the labels must still be legible after several years. Therefore, the special labels made of film are required here, which offer the desired security and long-term usability. Paper labels are less appropriate here, as they tear more quickly and would not withstand the temperatures.

In addition, the labels must have other properties so that they can be used in the automotive industry. Among other things, the labels must be flame retardant, thermally resistant up to 180 degrees Celsius and resistant to oil and petrol.

Food industry:

The food industry requires a particularly large number of labels, as almost every single product needs a separate label. The labels must contain important information about the food, including:

- Origin

- Shelf life (best before date)

- Ingredients

- Nutrients

- Allergens

- Net quantity

- Designation of the foodstuff

It should be noted that in addition to food labels, shipping labels are also required in this industry. The food has to be shipped so that it can be sold. In the food industry, there are strict regulations that must be adhered to in order to ensure food safety. Film labels are also recommended here. These can be used flexibly and also meet various temperature requirements.

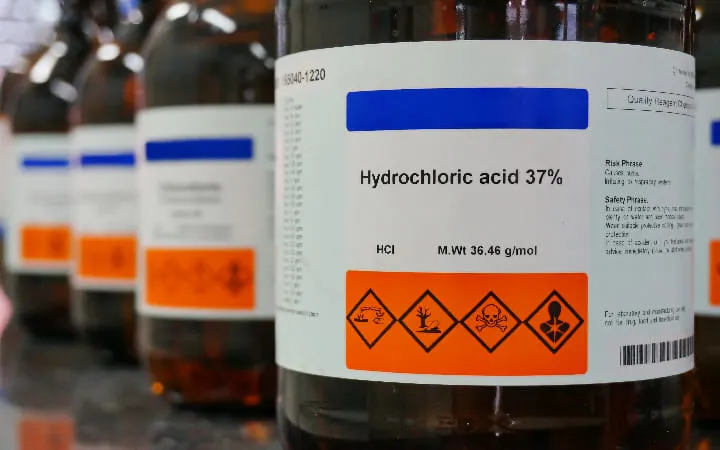

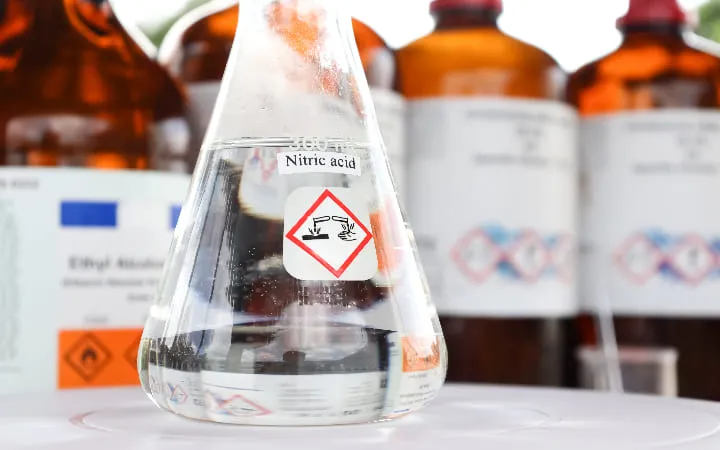

Chemical industry

In the chemical industry, labels are needed that can offer special and hard-wearing solutions. In this field, durable and also weather-resistant film labels are used. It is important that the labels adhere to different surfaces and can withstand difficult demands, such as:

- Dirt

- Oils and fats

- Cold and heat

- Humidity and moisture

- Solvent

This is exactly what the film labels made of various plastic materials offer. It is also essential to comply with regulations and standards for chemical labels, predominantly for hazardous goods labels, seawater-resistant labels and GHS labels (Globally Harmonised System of Classification and Labelling of Chemicals). The regulations are intended to ensure safety for humans, animals and the environment.

Advantages of film labels

The film labels from Labelprint24 are:

- tear-resistant

- robust

- moisture repellent

- dirt-resistant

- and scratch-resistant.

Accordingly, they have a very high resistance to water, oil, chemicals, grease and UV radiation. They are also popular in the industrial, cosmetics and chemical sectors, and some labels are also used in the food sector, for example in frozen food shelves. In addition, the film can be punched, folded, printed, glued and creased as desired. Our film labels even meet strict migration regulations, for example when handling food.

In addition, their robustness makes them suitable for outdoor use in transport and storage. Our film labels can be produced with different adhesives and plastics. This ensures the best hold and excellent quality in any environment.

An additional coating is not necessary for the film labels if they are only used outdoors, for example. However, a luxurious or stylish look can be achieved with a finish. And for special applications, an additional coating can of course be advantageous.

Not all plastics are the same. We have various films for you to choose from. Labelprint24 will be happy to advise you so that you can make a suitable decision. In our product configurator you can easily and quickly design your labels according to your wishes.

Instructions of the ordering process for film labels

To help you choose the right film labels, we provide you with our product configurator. Through this you have the possibility to individually produce your labels step by step. First, select the type of label you prefer. We have a large selection of different labels from deep-freeze labels to blank labels.

Next, you will be redirected to our label calculator. In the label calculator there are various parameters that you can determine yourself. You can start with the number of quantities and types. There you enter the desired total quantity - the minimum order quantity is 10 per variety. The number per type is only requested at the end of the order when the data is uploaded.

Then you can choose your label material. We offer different film materials, e.g. PP, PE or PVC film. These label materials can be equipped with different material properties. For example, you have the choice between different adhesives, where you will also be shown application examples and areas of use.

In the next step, specify the format and the winding direction. Width, height and corner radius must not exceed or fall below the following dimensions:

- Width: 10 - 314 mm

- Hight: 10 - 700 mm

- Corner radius: 0 - 10 mm

The next step is the cutting die, which is created from the selected dimensions. You have the option of specifying the winding direction yourself or having us specify it for you. The core diameter of your label roll can be 26, 40, 50 or 76 mm.

Now you can determine the colours of your labels. Labelprint24 offers you a 4-colour print with the Euroscale - in addition, there are also special colours. Finally, you can choose a coating for your labels - there is a protective lacquer and a protective laminate to choose from. Then determine the production and delivery time.

You can now complete your order and access the shopping cart.

If you need help or have any questions, please contact our customer support.

Why order from Labelprint24?

At Labelprint24 we offer you comprehensive and competent advice on all matters relating to labels and packaging. If you have any questions or other concerns regarding our labels, please feel free to contact our service team. Whether by telephone or in writing by e-mail, our team will be happy to advise you. Together we will find the right solution for you.

With our product configurator, you can design your own film labels in a few simple steps. You also benefit from fast shipping and short production and delivery times.