Pharmaceutical Packaging Standards in the UK: Ensuring Patient Safety and Compliance

The United Kingdom has a robust set of regulations and guidelines in place to ensure that pharmaceutical packaging meets the highest standards of safety, quality, and patient-centricity. These standards, enforced by the Medicines and Healthcare products Regulatory Agency (MHRA), cover various aspects of packaging, including labelling, child-resistance, anti-counterfeiting measures, and accessibility features like Braille. In this article, we'll explore the key pharmaceutical packaging standards in the UK and how providers like labelprint24.com help manufacturers meet these requirements.

Labeling Requirements: Clear, Comprehensive, and Compliant

One of the most critical aspects of pharmaceutical packaging is labelling. The MHRA mandates that labels must contain essential information, such as the name of the medicine, strength, route of administration, posology, and warnings. This information should be clearly displayed together to ensure that patients can easily understand and follow the instructions for safe and effective use.

In addition to these basic requirements, the MHRA also specifies that multi-language packs are allowed in the UK, as long as all information complies with UK requirements. This flexibility enables pharmaceutical companies to streamline their packaging processes while still meeting the needs of diverse patient populations.

Accessibility Features: Braille and Beyond

Ensuring that pharmaceutical packaging is accessible to all patients, including those with visual impairments, is a crucial aspect of the UK's standards. Braille is required on medicine packaging, except for small containers under 10ml. The name of the medicine must be embossed in Braille on the label to enable visually impaired patients to identify their medications easily.

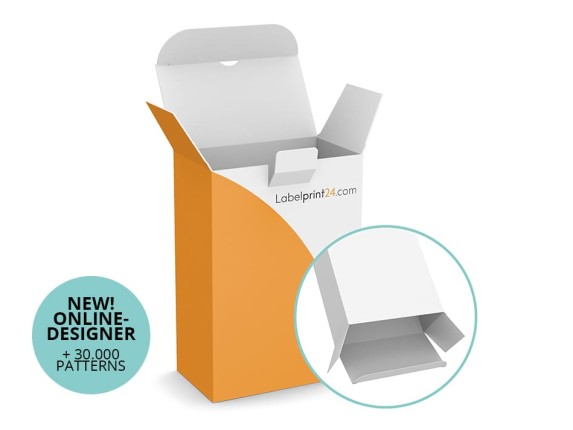

Labelprint24.com, an online provider of the All4Labels Group, offers a range of packaging solutions that incorporate Braille and other accessibility features. Their expertise in producing folding cartons, labels, and tubes that meet the quality standards for pharmaceutical and healthcare products ensures that manufacturers can provide patient-friendly packaging that complies with UK regulations.

Child-Resistant Packaging: Protecting Young Lives

Child-resistant packaging is another essential aspect of pharmaceutical packaging standards in the UK. The MHRA mandates that products containing aspirin, paracetamol, or over 24mg of elemental iron must have child-resistant packaging, unless they are in effervescent or single-dose form. This requirement helps prevent accidental ingestion by curious children, thus reducing the risk of poisoning and other adverse events.

Labelprint24.com offers a variety of child-resistant packaging options, such as folding boxes with security tabs and specialised closures, to help pharmaceutical manufacturers meet this critical safety requirement.

Anti-Counterfeiting Measures: Combating Falsified Medicines

To combat the growing threat of falsified medicines, the MHRA requires that prescription medicine packs include safety features, such as a unique identifier (2D data matrix code) and an anti-tampering device. These measures help ensure that patients receive genuine, safe, and effective medications, while also enabling more efficient tracking and tracing of products through the supply chain.

Labelprint24.com's range of safety labels, including hologram and tamper-evident options, can help pharmaceutical manufacturers implement these anti-counterfeiting measures effectively and efficiently.

Adapting to Post-Brexit Changes

Following the UK's departure from the European Union, the MHRA has introduced new requirements for pharmaceutical packaging. When a product receives a new GB marketing authorization post-Brexit, the packaging must be updated within 24 months to include the new MA holder details, MA number, and manufacturer address. This requirement ensures that patients have access to accurate and up-to-date information about their medications.

Labelprint24.com's flexible and responsive production processes enable pharmaceutical manufacturers to quickly adapt their packaging to meet these post-Brexit requirements, ensuring continuous compliance with UK regulations.

Conclusion

Pharmaceutical packaging standards in the UK are designed to prioritise patient safety, accessibility, and information clarity. By adhering to the MHRA's requirements for labelling, child-resistance, anti-counterfeiting, and Braille, pharmaceutical manufacturers can ensure that their products are safe, effective, and user-friendly. To learn more about labelprint24.com's pharmaceutical packaging solutions, visit their Folding boxes, Labels, and Laminate tubes pages, or explore their commitment to quality and safety.

Specialist providers like labelprint24.com play a crucial role in helping pharmaceutical companies meet these strict regulatory standards. With their expertise in producing high-quality packaging components that comply with UK requirements, labelprint24.com enables manufacturers to focus on developing innovative and life-saving medications while ensuring that their packaging meets the highest standards of safety and compliance.